Differences in Thinking Between Japan and Europe

| Traditional Japanese Way of Thinking |

|---|

Zero accidents (focus on number of accidents)

|

| Western Way of Thinking |

|---|

Zero danger (emphasis on major disasters)

|

Recurrence prevention measures and horizontal deployment

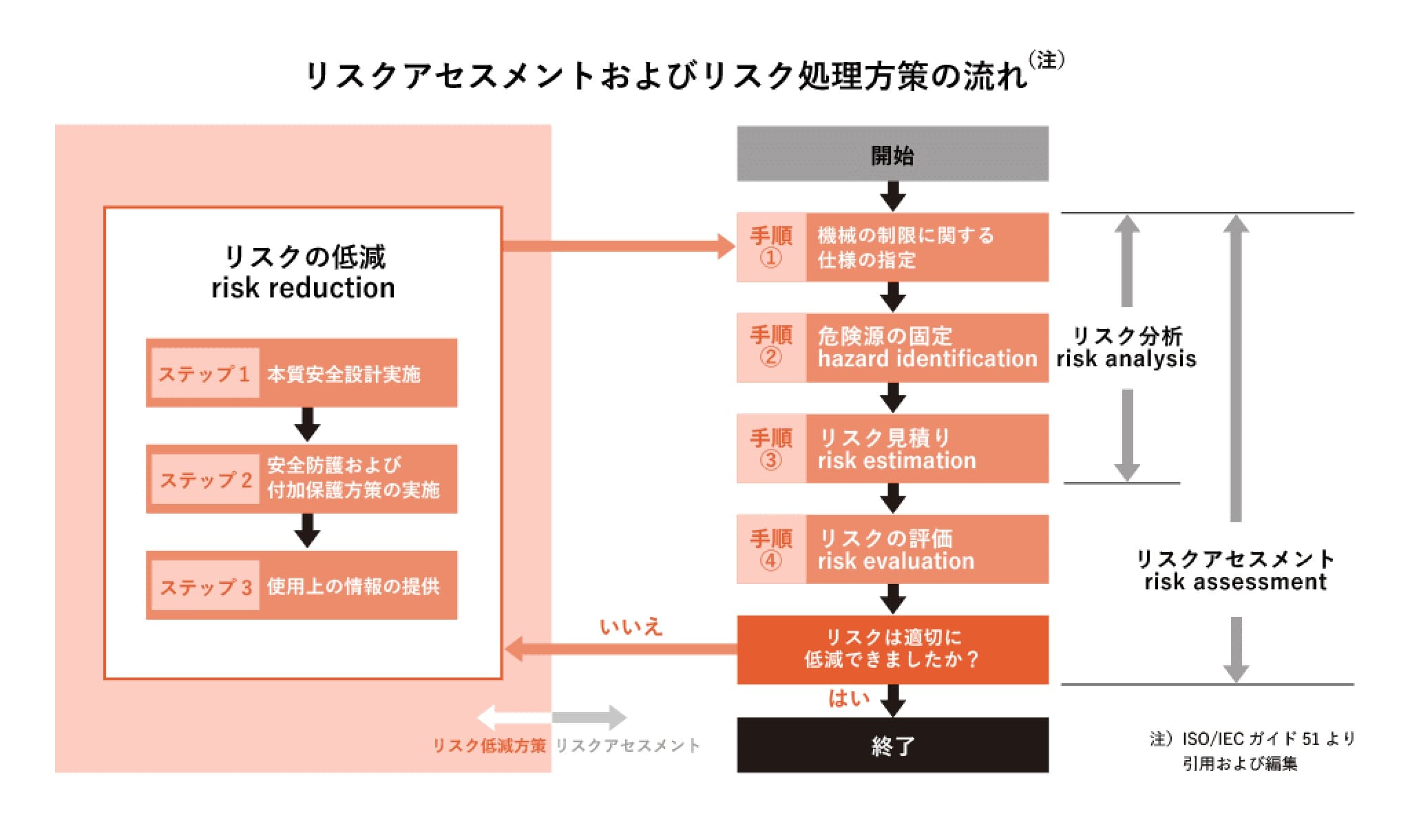

Risk Assessment

EN954-1/ISO13849-1 Safety Category

Click here for an overview of machine safety and related products.

Click here for safety categories and performance levels.

Contact Our Team

ROSS employs a powerful team of experts with vast experience in fluid power able to help you find a solution for your safety goals. Whether it be a custom solution, a current product, application, or safety course, ROSS is here to provide just what you need with your business specifications in mind.